Mixer / bin blender

-

ZTH-800 Automatic Lifting

The machine is a new machine researched and developed successfully by our company according to China's actual conditions after absorbing and digesting internationally advanced technology.

Email Details

1.The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts.

2.The mixing bin forms an included angle of 30 °with the rotation axis.

The materials in the mixing bin rotate along with the gyrator and make tangential movement along the hopper walls, producing strong turning and high-speed-tangential movement and achieving the best mixing infrared safety device and the discharging butterfly valve with the mis-operation preventer to ensure safe production.

3.The materials can go through different working procedures in the same bin without the need of frequent material transferring, material charging, etc.

4.The machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets GMP requirements for medicine production.

5. Good control system sensitivity, compact machine structure and stable and reliable running. -

ZTH-200 IBC bin blender Dry Powder Mixer

1.The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts.

Email Details

2.The mixing bin forms an included angle of 30 °with the rotation axis.

The materials in the mixing bin rotate along with the gyrator and make tangential movement along the hopper walls, producing strong turning and high-speed-tangential movement and achieving the best mixing infrared safety device and the discharging butterfly valve with the mis-operation preventer to ensure safe production.

3.The materials can go through different working procedures in the same bin without the need of frequent material transferring, material charging, etc.

4.The machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets GMP requirements for medicine production.

5. Good control system sensitivity, compact machine structure and stable and reliable running. -

ZTH-1500 360° rotation mixing bin blender lifting machine

1. HMI and PLC control, can display English/Chinese

Email Details

2. 5 level password protection for operation

3. Bin-in-place detection: Automatic positioning of bin after completion of mixing time, vertical with discharging valve at bottom

4. Key Switch (for main On-Off)

5. Mixing speed and time setting

6. RPM and timer display (to be displayed on HMI)

7. Receipe storage (for mixing time, mixing speed, etc)

8. Monitoring of fault and blocking signals;

9. Monitoring the operation of all mixing programs;

10. Archiving keeping data on the progress of the technological process

11. USB data output

12. Equipped with power shutdown protection: Phoenix UPS

13. Complying 21CFR Part11 requirements -

220V/380V double arm mixing machine for powder

The machine is composed of two machine basses, rotation frame, rotation system, lifting system, control system, etc.

Email Details

Work principle video for reference:

https://youtu.be/GOeUR5QPL8M

Push the mixing bin into the rotation frame and complete the positioning. -

ZTH-2000 Automatic Lifting Bin Blender Auto Powder Blender Mixer Blending Machine

The machine is composed of two machine basses, rotation frame, rotation system, lifting system, control system, etc.

Email Details

Work principle video for reference:

https://youtu.be/GOeUR5QPL8M

Push the mixing bin into the rotation frame and complete the positioning. -

Mixing Evenly 300L 304 Stainless Steel Power Granules Drum Dryer Blending Machine Double Cone Bin Blender

1.High hardness

Beautiful and elegant, easy to clean

2.Aging resistance

Has good aging resistance performance

3.Not easily damaged

Durable and long-lasting, the product has a long service lifeblender power consumption Cereal Mixer Industrial Vertical Grain Machine Waist drum type dry powder feed mixerEmail Details -

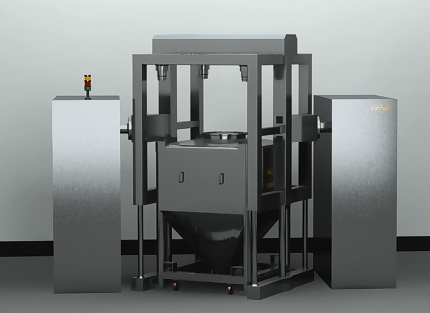

IBC tank Powder Mixing Blender Interchangeable Rotation Hopper Mixer Single-column Lifting Bin Blender

The HLT single-column lifting bin mixer is widely used for mixing different components of powders with powders, powders with granules and granules with granules in the production procedure in the pharmaceutical industry. The machine is provided with such functions as automatic lifting, mixing, lowering, etc. It can be equipped with various specifications of bin for mixing operation. It is suitable for mixing medicines of different varieties and different batches in large and medium-sized pharmaceutical enterprises according to process requirements. Multiple purposes can be realized in one machine.

Automatic Homogenizer Powder Blender New Single Column Bin Mixer Single Column Lifting Hopper BlenderEmail Details -

2000L Stainless Steel Mixing Machine Granule Powder Mixer Vertical Bin Blender

1. High efficiency: interrupted bionic wire rod, effectively prevent material bonding, can achieve the ideal mixing effect in a short time;

Email Details

2. High uniformity: wall attachment design, chamber bottom scientific design, high mixing uniformity;

3. Low residue: scientific design at the bottom, no dead Angle, no residue when discharging;

4. No leakage: Scientific design ensures zero leakage of rotating shaft and discharge port;

5. High safety factor: The mixing process is very soft, with automatic operation timing, overload protection, safety alarm and other functions;

6. Wide applicability: can add chopper module, and spraying and other functions. -

Hot

Single Column Lifting Bin Blender

Changeable bins design for various capacity

Email Details

Human/ machine/ product safety

High automation and efficient blending

Simple operation and easy to clean