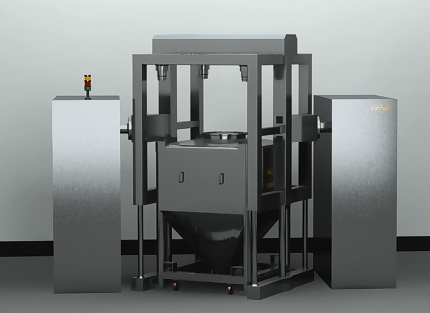

ZTH-1500 360° rotation mixing bin blender lifting machine

ZTH-1500 360° rotation mixing bin blender lifting machine

- Wonsen

- China

- 120 days

- Strong

1. HMI and PLC control, can display English/Chinese

2. 5 level password protection for operation

3. Bin-in-place detection: Automatic positioning of bin after completion of mixing time, vertical with discharging valve at bottom

4. Key Switch (for main On-Off)

5. Mixing speed and time setting

6. RPM and timer display (to be displayed on HMI)

7. Receipe storage (for mixing time, mixing speed, etc)

8. Monitoring of fault and blocking signals;

9. Monitoring the operation of all mixing programs;

10. Archiving keeping data on the progress of the technological process

11. USB data output

12. Equipped with power shutdown protection: Phoenix UPS

13. Complying 21CFR Part11 requirements

Products Description

Application

The machine is provided with such functions as automatic lifting, mixing, lowering, etc. A bin mixer and several mixing bin of different specifications can meet the mixing requirements of different batches and diversified varieties of products. It is an ideal machine for mixing in manufacturing plants. It is also widely used in such industries as chemical, food industry, etc.

Working principle

The machine is composed of two machine bases, rotation frame, rotation system, lifting system, control system, etc. Push the mixing bin into the rotation frame and complete the positioning. Start the control system to lift the rotation frame to the mixing height and clamp it reliably. The driving system will carry out automatic mixing according to the set time, rotation speed and other data. After the mixing operation is finished, the rotation frame will stop vertically, the bin will automatically fall to the ground, the machine will stop and process data will be printed. The bin is transferred to the next procedure.

Technical Parameters

Certifications

Our Advantages

Why Choose Us

Manufacturing Technique

Exhibition

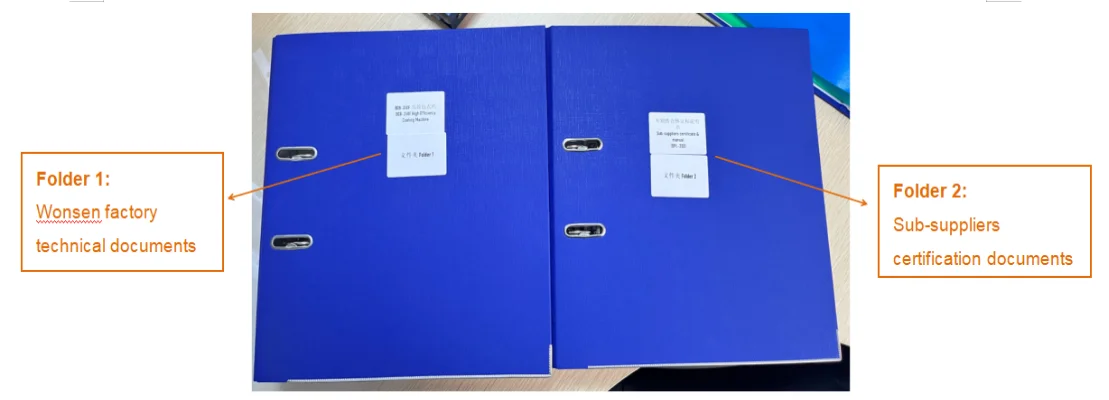

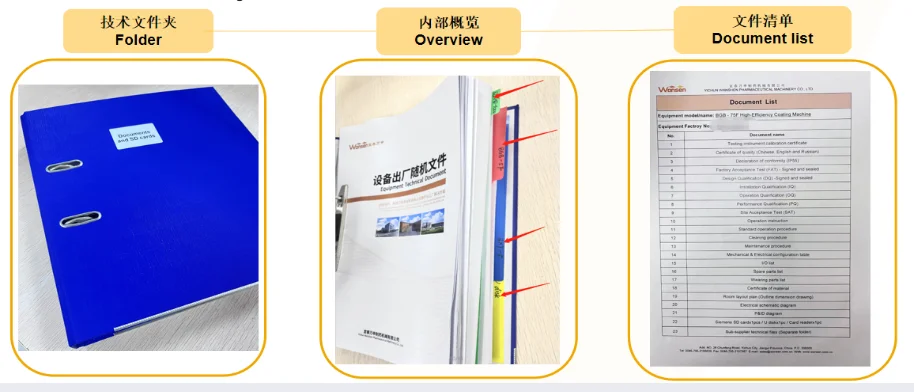

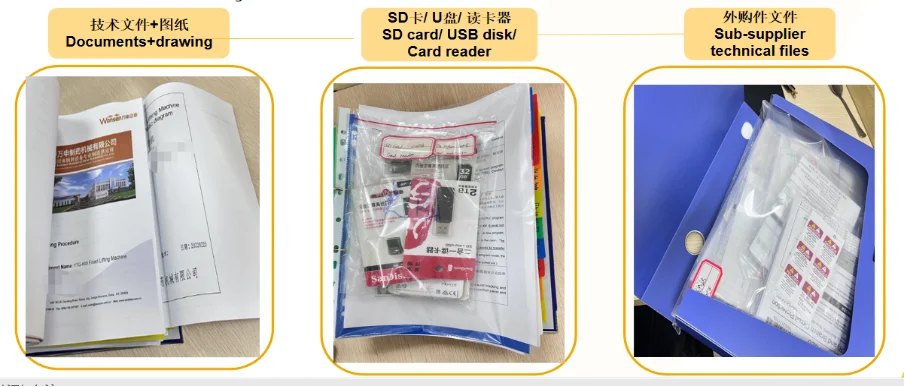

Technical Document