High Quality Customized Powder Dryer Vacuum Drum Drying Machine Double Cone Rotary Vacuum Dryer

High Quality Customized Powder Dryer Vacuum Drum Drying Machine Double Cone Rotary Vacuum Dryer

- Wonsen

- China

- 120 days

Double cone rotary vacuum dryer is a drying equipment which integrates mixing and vacuum drying. The process of vacuum drying is to place the material to be dried inside the sealed cylinder, and heat the material continuously while vacuum-pumping with the vacuum system, so that the water inside the material diffuses to the surface through the pressure difference or concentration difference, and the water molecules (or other non-condensing gases) obtain enough kinetic energy on the surface of the material and diffuse to the low-pressure space of the vacuum chamber after overcoming the mutual attraction between molecules. It is removed by the vacuum pump to complete the separation from the solid.

Products Description

Features

Double cone rotary vacuum dryer is a drying equipment which integrates mixing and vacuum drying. The process of vacuum drying is to place the material to be dried inside the sealed cylinder, and heat the material continuously while vacuum-pumping with the vacuum system, so that the water inside the material diffuses to the surface through the pressure difference or concentration difference, and the water molecules (or other non-condensing gases) obtain enough kinetic energy on the surface of the material and diffuse to the low-pressure space of the vacuum chamber after overcoming the mutual attraction between molecules. It is removed by the vacuum pump to complete the separation from the solid.

Application

This machine is suitable for vacuum drying and mixing of powder and granular materials in food, chemical and other industries, especially for materials with the following requirements:

*Suitable for materials can not accept high temperature heat sensitive materials;

*Easy to oxidize, dangerous materials

*Materials that need to recover solvents and toxic gases

*Materials requiring very low residual volatile matter content

*Requires full mixing, uniform material

Working principle

* In the process of vacuum drying, the pressure in the cylinder is always lower than the atmospheric pressure, the number of gas molecules is small, the density is low, and the oxygen content is low, so that the drugs that are easy to oxidize can be dried and the chances of bacteria contamination of the materials can be reduced.

* Since the temperature of the wet component in the vaporization process is proportional to the steam pressure, when vacuum drying, the wet component of the material can be vaporized at low temperature to achieve low temperature drying, especially suitable for the production of drugs with heat-sensitive materials.

* Vacuum drying can eliminate the surface hardening phenomenon easily produced by atmospheric hot air drying, this is because the pressure difference between the vacuum drying material and the surface is large, under the pressure gradient, the water quickly moves to the surface, there will be no surface hardening.

* Due to the small temperature gradient between the inside and outside of the material during vacuum drying, the wet component can move and collect independently due to reverse osmosis, effectively overcoming the separation phenomenon caused by hot air drying.

Certifications

Our Advantages

Why Choose Us

Manufacturing Technique

Exhibition

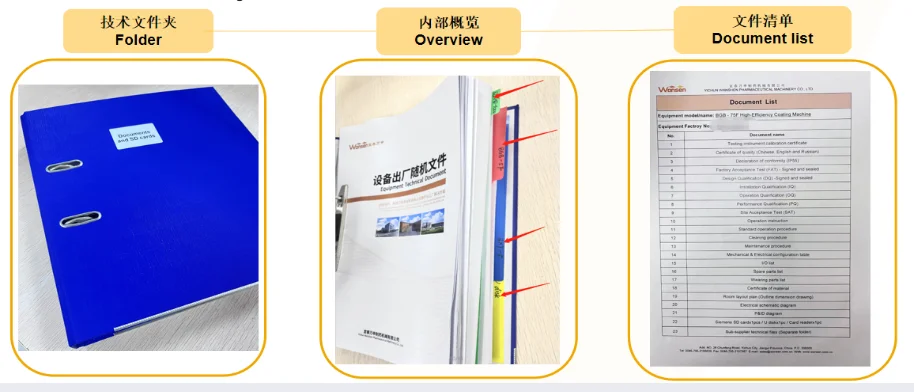

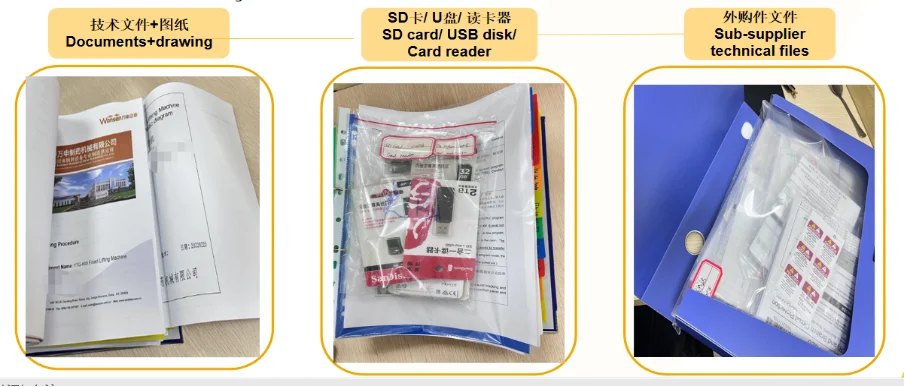

Technical Document