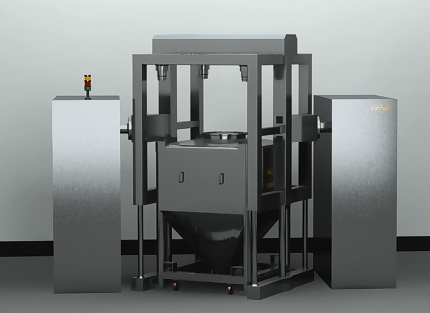

ZTH-200 IBC bin blender Dry Powder Mixer

- Wonsen

- China

- 120 days

- Strong

1.The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts.

2.The mixing bin forms an included angle of 30 °with the rotation axis.

The materials in the mixing bin rotate along with the gyrator and make tangential movement along the hopper walls, producing strong turning and high-speed-tangential movement and achieving the best mixing infrared safety device and the discharging butterfly valve with the mis-operation preventer to ensure safe production.

3.The materials can go through different working procedures in the same bin without the need of frequent material transferring, material charging, etc.

4.The machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets GMP requirements for medicine production.

5. Good control system sensitivity, compact machine structure and stable and reliable running.